Punch Tip Deflection Kit

Genuine Elizabeth Precision. Zero Compromise.

In pharmaceutical and nutraceutical compression, your tooling alignment is critical. A single bent punch tip can score a die bore, create “J-hook” burrs, and jeopardize an entire production campaign.

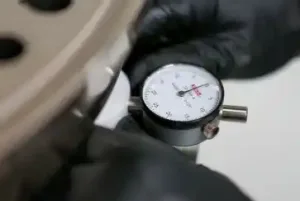

The Elizabeth Punch Tip Deflection Kit brings OEM-level accuracy into your maintenance room. Designed with a universal fixture to accommodate various punch barrel diameters, this kit provides a rapid, fail-safe method to verify that your tooling is straight, true, and ready for the press.

Why Choose the Elizabeth Punch Tip Deflection Kit?

OEM Quality: Engineered to work with your tablet presses and tooling.

User-Friendly Operation: Simple setup allows operators to quickly verify punch tip condition without extensive training or complex calibration.

Shop-Floor Durability: Built to withstand the rigors of daily use in a tool room while maintaining laboratory-grade accuracy.

Prevent Costly Damage to Your Press and Tooling

Deflection is often invisible to the naked eye. This kit detects run-out (wobble) in the punch tip relative to the barrel to stop issues before they start.

Stop Die Wear: Prevent bent tips from scraping and scoring expensive die walls.

Improve Tablet Consistency: Eliminate capping and flashing caused by off-center compression.

Validate Repairs: The ideal tool for checking punches after polishing or tip repair.

Equip Your Production with the Best

Don’t trust your expensive tablet press tooling to generic tools. Invest in the accuracy and durability of Elizabeth.

Talk to a Tooling Expert

Fill out the form for more information regarding punch tip deflection kits.

Why is checking for tip deflection important?

A bent tip acts like a cutting tool against your die wall. Measuring deflection prevents the punch from scraping the die, which saves you money on replacement dies and prevents "J-hook" burrs from forming.

How often should I check my tooling?

LFA recommends checking punches for deflection every time they are removed for cleaning or polishing, or immediately if you notice unusual noise ("clicking") coming from the turret during production.

Is the kit difficult to use?

No. The kit is designed for shop-floor efficiency. An operator can mount a punch and perform an inspection in seconds, making it easy to incorporate into your regular maintenance routine.

What is the acceptable tolerance for deflection?

While this depends on your specific tablet size and speed, a general rule of thumb is that tip run-out should not exceed 0.025mm (0.001"). If the dial indicates movement beyond this, the punch should be inspected further or replaced.